Page 37 - General_Catalogo_Acessorios_2020

P. 37

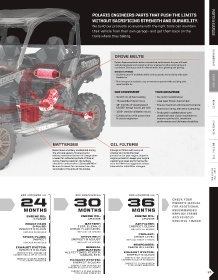

FOR THE LIFE POLARIS ENGINEERS PARTS THAT PUSH THE LIMITS PARTS & GARAGE

WITHOUT SACRIFICING STRENGTH AND DURABILITY.

We build our products so anyone with the right tools can maintain

OF YOUR RIDE their vehicle from their own garage - and get them back on the

trails where they belong.

AIR FILTERS

DRIVE BELTS

MAINTENANCE Critical to engine performance and Polaris Engineered belts deliver unmatched performance for your off-road OIL & LUBRICANTS

reliability. A clogged air filter can restrict

TIP air flow to the engine leading to reduced vehicle. Developed and tested on all our engines for all environments and

engine performance. Dirt and debris

ingestion can damage the engine leading conditions. Check your belt for delamination, hour glassing and glazing.

to reduced engine life or catastrophic BREAK-IN PERIOD

BREAK-IN PERIOD failure. Polaris recommends changing the • Use lower gear (if available) while varying speeds and avoiding wide open

vehicle’s air filter at the specified throttle for

The break-in period for your new intervals outlined in the owner’s manual, • If no low gear is available, vary at moderate speeds while avoiding wide MAINTENANCE

which may be shorter if your vehicle is

GENERAL is the first 25 hours of subject to severe conditions. open throttle for

operation, or the time it takes to

MAINTENANCE

use the first two tanks of fuel. No OUR INVESTMENT YOUR ADVANTAGE

single action on your part is as BRAKE PADS • 32,187 km of field testing • No clutch recalibration

important as a proper break-in

period. Careful treatment of a new Check your brakes if you are close to the • Thousands of dyno hours • Less wear & tear due to heat

recommended service interval, hear

engine will result in more efficient grinding when applying the brakes, your • 18+ months of development • Ensure maximum vehicle performance HD PARTS

performance and longer life for the vehicle is taking longer to stop or if you (3,000+ design hours) per belt • More time riding, less time wrenching

engine. Perform the listed have to apply more pressure to your pedal • 1200+ vehicle validation hours • Produced in collaboration with

procedures carefully. to engage the brakes. Check the brake • Collaboration with powertrain powertrain and clutch engineers to

discs for signs of cracks, excessive & clutch engineers ensure a perfect fit, maximum

corrosion or warping.

NOTICE: Excessive heat build-up during the first If the brake pads are contaminated with performance and ultimate durability

three hours of operation will damage

close-fitted engine parts. Do not operate at full oils or grease (petroleum products), brake SERVICE PARTS

pads have to be discarded and replaced.

throttle or high speeds for extended periods

during the first three hours of use. Discs need to be cleaned with brake

cleaner or alcohol based cleaner only.

BATTERIES OIL FILTERS

HALF SHAFT

Never leave a battery unattended during Change oil filters with every oil BATTERY & LIFTS

Extreme elements can contribute the storage season. To ensure your change to provide the best

to axle failure when grease battery maintains its level of charge when protection for your engine. Superior

escapes the joint. This usually unused for extended periods of time or engine protection keeps your engine

occurs if the CV boot becomes during freezing weather, the battery operating at peak performance. Be

compromised. Full replacement should be connected to a BatteryMINDer ® . sure to follow the suggested service

or part specific available. Be sure to check for corrosion from the intervals for oil/oil filter changes.

terminals to the ends of the cables. & TRAILERING VEHICLE CARE

MAINTENANCE SCHEDULE

25 HRS/400 km 50 HRS/800 km 100 HRS/1600 km 150 HRS/2400 km 200 HRS/3200 km 350 HRS/4020 km 500 HRS/8045 km

BREAK-IN 6 12 18 24 30 36 CHECK YOUR

OWNER'S MANUAL

MAINTENANCE FOR ADDITIONAL

MONTHS MONTHS MONTHS MONTHS MONTHS MONTHS RECOMMENDED

SERVICE ITEMS

ENGINE OIL: EXHAUST SYSTEM: ENGINE OIL: ENGINE OIL: ENGINE OIL: ENGINE OIL: ENGINE OIL: AND VEHICLE-

CHANGE INSPECT & CLEAN CHANGE CHANGE CHANGE CHANGE CHANGE

INSPECT FOR LEAKAGE OR SPECIFIC TIMING

GENERAL CARBON BUILD UP AT JOINTS DRIVE BELT: BATTERY: BRAKE PADS BATTERY: AIR FILTER:

LUBRICATION: INSPECT & CLEAN SCREEN TYPE INSPECT & ADJUST TEST, CLEAN, & & FLUID: TEST, CLEAN, & INSPECT, CLEAN

ALL FITTINGS, PIVOTS, SPARK ARRESTOR REPLACE AS NEEDED CHECK FLUID LEVEL INSPECT & CLEAN CHECK FLUID LEVEL REPLACE AS NEEDED

CABLES, ETC. REPLACE AS NEEDED REPLACE AS NEEDED REPLACE AS NEEDED

GENERAL TRANSMISSION COOLANT:

AIR FILTER: LUBRICATION: FLUID: DRIVE BELT: SPARK PLUGS: DRIVE BELT: CHECK LEVEL

INSPECT & CLEAN ALL FITTINGS, PIVOTS, CHANGE INSPECT & ADJUST INSPECT INSPECT & ADJUST REPLACE EVERY 2 YEARS

REPLACE AS NEEDED CABLES, ETC. REPLACE AS NEEDED REPLACE AS NEEDED REPLACE AS NEEDED

EXHAUST SYSTEM: GEARCASES:

EXHAUST SYSTEM: DRIVE BELT: INSPECT & CLEAN TIRES: EXHAUST SYSTEM: GENERAL CHECK OIL LEVEL

INSPECT & CLEAN INSPECT & ADJUST INSPECT FOR LEAKAGE OR INSPECT CONDITION INSPECT & CLEAN LUBRICATION:

INSPECT FOR LEAKAGE OR CARBON BUILD UP AT JOINTS & PRESSURE INSPECT FOR LEAKAGE OR ALL FITTINGS, PIVOTS, EXHAUST SYSTEM:

CARBON BUILD UP AT JOINTS REPLACE AS NEEDED CARBON BUILD UP AT JOINTS CABLES, ETC. INSPECT & CLEAN

INSPECT & CLEAN SCREEN

INSPECT & CLEAN SCREEN TYPE SPARK ARRESTOR EXHAUST SYSTEM: INSPECT & CLEAN SCREEN INSPECT FOR LEAKAGE OR

TYPE SPARK ARRESTOR INSPECT & CLEAN TYPE SPARK ARRESTOR EXHAUST SYSTEM: CARBON BUILD UP AT JOINTS

INSPECT FOR LEAKAGE OR INSPECT & CLEAN INSPECT & CLEAN SCREEN

CARBON BUILD UP AT JOINTS INSPECT FOR LEAKAGE OR TYPE SPARK ARRESTOR

CARBON BUILD UP AT JOINTS

INSPECT & CLEAN SCREEN

34 TYPE SPARK ARRESTOR INSPECT & CLEAN SCREEN 35

35

TYPE SPARK ARRESTOR